Why Choose Air Dimensional Air Gages

If you’re an engineer, machinist, or industrial designer, you probably have a set of air gauges in your workshop. Air gauges are a convenient and inexpensive tool for measuring diameters. They can be quickly and easily set up, take up little bench space and measure with high accuracy. Air gauges also come in all shapes and sizes to fit the many different kinds of jobs out there today.

Air Gages generally cost less.

Air gages are generally cheaper than the other types of gages. But why? Well, air gages are mechanical devices that use air pressure to measure the dimensions of an object. The main difference between air and electronic or laser gages is that they’re not as precise as electronic or laser models.

Electronic models use lasers to measure objects’ dimensions quickly and precisely. These models can cost up to USD 100,000! The downside is that you need special training to operate them; if you don’t have this training, it could cost even more money for someone else who does have this training to come out and service your equipment.

Other types of mechanical sensors, such as eddy current transmitters, work well too but require specialized training as well—and again, these can range from $50k-$100k depending on brand/model.

Want to know more about air gaging? Here is a Mahr gaging webinar on air gaging.

Air Gages work on all materials.

One of the benefits of air gages is that they can work on a wide range of materials, including metals, plastics, and ceramics. This makes them highly versatile and helpful in various manufacturing and inspection applications. Additionally, air gages can operate effectively in multiple environments, including dusty, dirty, or otherwise challenging environments. This means you can use them in your facility without worrying about interference from the surrounding environment. Overall, the versatility and robustness of air gages make them an excellent choice for a wide range of measurement applications.

Air Gages can be quick & easy set up.

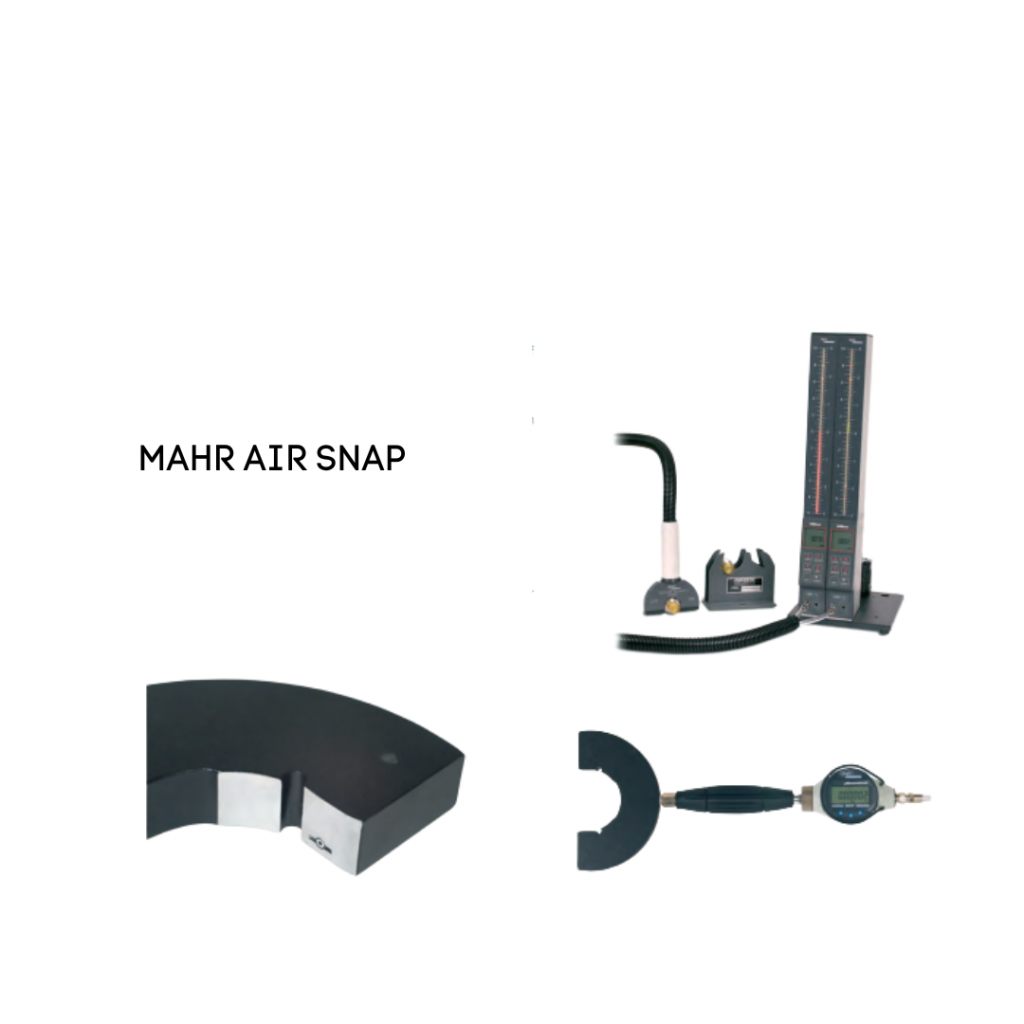

One of the advantages of using air gages for measurement is that they are quick and easy to set up. Air gages typically consist of a measuring head, an air supply, and a display unit, which can be easily assembled and connected to form a complete measurement system. This process can be completed in just a few minutes, making it easy to quickly get up and running with an air gauge system. Additionally, many air gages are designed with user-friendly interfaces that make inputting and retrieving measurement data easy, further simplifying the setup process.

Overall, the quick and easy setup of air gages makes them an excellent choice for those who need to start measuring quickly and efficiently.

Set them up in seconds, minutes, or even less than five minutes. The best part is that you don’t need any special tools or knowledge to do so.

Measure with a high degree of accuracy

Air gages are accurate, but that’s not all they have. When measuring an air gauge, accuracy measures how close the reading on the indicator comes to being correct. Precision is how much variation there is in those measurements; if you measured something three times using an air gauge and got three different readings, your precision would be low.

Accuracy and precision are not interchangeable terms: accuracy refers specifically to whether or not a measurement was correct; precision refers more generally to how much variation there was from one measurement to the next. For example, if my friend tells me that he weighs 160 pounds (80 kilograms), then I can confidently say that his weight is within 4% of what it should be because 80 kg x 0.04 = 3 kilograms off target—but this does not mean he has precise scales!

Compact Air Gages Offer Convenient and Efficient Measurement

Unlike their hydraulic and pneumatic counterparts, air gages are small and portable. This is why they can be used in tight spaces where other types of gages would not be able to fit. They are also versatile enough for use on various tasks such as calibration checks or setting up new equipment.

They’re easy to store, too! Air Gages take up little bench space compared with their counterparts because they can be stacked easily while maintaining accuracy through a special fluid-filled enclosure called an air cell inside the gage.

Air gauges are a convenient and inexpensive tool for measuring diameters. They can be quickly and easily set up, count with high accuracy, take up little bench space, and are easy to use. Take precision and accuracy to the next level with Pride Gage. Our team team of experts has decades of experience in the field, and we use only the highest quality manufactures to ensure that your air gages are accurate and reliable.

Upgrade your shop floor with air gaging that offers extreme accuracy, repeatability, and reliability in every measurement. Choose Pride Gage for your air gaging desires today and experience the difference.

Keyanna Harper

Pride Gage Content Strategist

Read About Me to learn more.